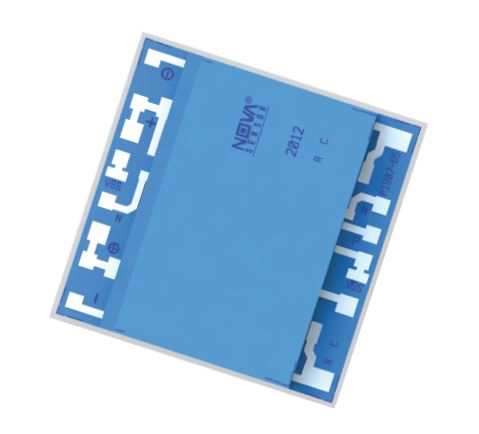

NovaSensor PT1907

Pressure Sensor Die

NovaSensor PT1907 is a piezoresistive sensor die that is designed for combined pressure and temperature measurements in harsh media. Pressure is applied from the backside of the die, which eliminates direct contact between the topside of the sensor circuitry and the applied media. This allows PT1907 to measure pressure and temperature in aggressive liquids and gases.

A vacuum reference cavity made with a Silicon cap on top of die is used for absolute pressure measurement. PT1907 also features excellent long-term stability and repeatability (< 0.1% / year typical), made possible by the NovaSensor SenStable® process.

The integrated on-chip temperature sensor allows for high accuracy measurement of temperature and improves accuracy of pressure measurement.

- Automotive systems

- Process control systems

- Aerospace

- Pressure and temperature measurements in aggressive media

- Harsh media compatibility

- Highly reliable, solid state silicon pressure sensor die pressurized from back (cavity) side

- Pressure Ranges: 60, 120,180, 300, 450, 600 and 1000 PSIA

- Temperature Range: -40°C to 150°C

- On-chip temperature sensor

- Die Dimensions (L x W x H): 1.9 mm x 1.9 mm x 1.6 mm (with glass), 2.0 mm x 2.0 mm x 0.8 mm (without glass)

- Flexible bond pads configuration allows for wire bonding, either to only one side or two sides of the die

| Pressure Sensor Specifications | |||

| General | Value | Units | Notes |

| Pressure Range | 60, 120,180, 300, 450, 600, 1000 | PSIA | |

| Maximum Overpressure | 2X | Rated Pressure | |

| Backside Burst Pressure | 10X >6000 |

PSI | 2, 6 |

| Electrical @ 25°C, Unless noted | Value | Units | Notes |

| Excitation (DC) | 1 | mA | |

| 5 | Volt | 10VDC Max | |

| Bridge Resistance | 5,000 ±20% | Ω | |

| Environmental | Value | Units | Notes |

| Operating Temperature Range | -40 to 150 | °C | 2 |

| Storage Temperature Range | -55 to 160 | °C | |

| Mechanical | Value | Units | Notes |

| Dimensions | 1.9 x 1.9 x 1.6 2.0 x 2.0 x 0.8 |

mm with glass mm without glass |

8 |

| Bond Pad Dimensions | 0.10 x 0.10 | mm L x W | 9 |

| Media Compatibility | Silicon and Borosilicate Glass | ||

| Pressure Sensor Performance Parameters(1) | Value | Units | Notes |

| Zero Offset | ±10 | mV/V | |

| FSO | 160 ±45 | mV | 3 |

| Pressure Linearity | ±0.2 | %Span | 4, 7 |

| Pressure Hysteresis | ±10 | µV/V | 5, 7 |

| Temperature Coef. of Zero | ±5 | µV/V/°C | 5, 7 |

| Temperature Coef. of Resistance | 0.27 | %°C | 5, 7 |

| Temperature Coef. of Sensitivity | -0.19 | %°C | 5, 7 |

| Thermal Hysteresis of Zero | ±25 | µV/V | 5, 7 |

| Temperature Sensor Specifications | |||

| General | Value | Units | Notes |

| Temperature Range | -40 to 150 | °C | |

| Electrical | Value | Units | Notes |

| Excitation (DC) | 10-100 | µA | 13 |

| Performance Parameters(10) | Value | Units | Notes |

| Zero | 0.625 | V | 7, 11 |

| Sensitivity | -2.15 | mV/°C | 7, 12 |

| FSO | 405 | mV | 7, 12 |

| Linearity | ±0.1 | % | 7, 12 |

| Zero Pressure Sensitivity | ±10 | µV/PSI | 7 |

|

Notes:

|

|||