Thermometrics NTC Thermistors

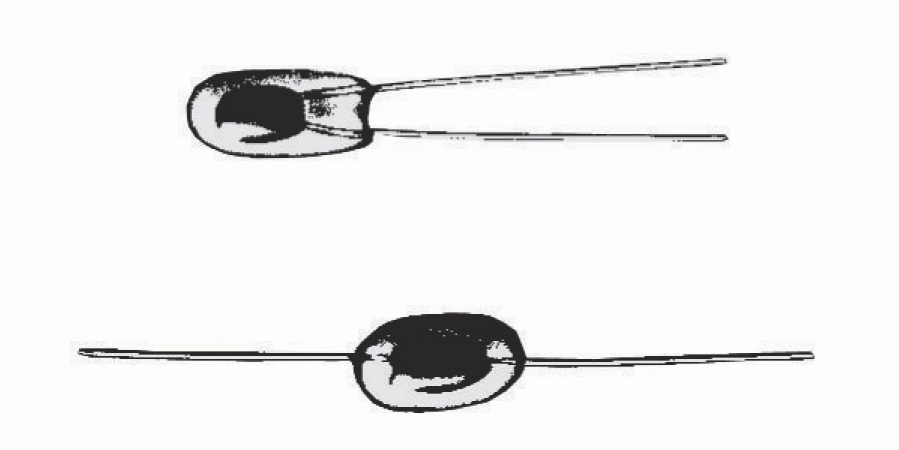

Glass BR Series - Glass-Encapsulated Bead

Thermometrics BR Series of Glass-Encapsulated Bead Thermistors consists of glass-encapsulated bead thermistors on fine diameter (alloy or platinum) lead wires. Rugged glass encapsulation provides hermetic seal and better strain relief than glass-encapsulated bead thermistors. Suitable for self-heated applications, such as liquid level sensing or gas flow measurement. Recommended for applications where the customer will perform further assembly operations.

- Low cost temperature measurement, control and compensation

- Self-heated applications, such as liquid level sensing or glass flow measurement

- Applications where the customer will perform further assembly operations

- Fast thermal response times

- Rugged glass encapsulation provides hermetic seal and better strain relief than glass-encapsulated bead thermistors

- Long term stability

- Unaffected by severe environmental exposures, including nuclear radiation

- Normal operating/storage temperatures range from -112°F (-80°C) to: 221°F (105°C) for Material system E0, 392°F (200°C) for Material systems A1 through A4, 572°F (300°C) for Material systems A5 through D17

- Intermittent operation to 600°C

| Thermistor Series: | BR11 | BR14 | BR16 | BR23 | |

| Body Dimensions | Nominal Diameter | 0.011 in (0.28 mm) | 0.014 in (0.36 mm) | 0.016 in (0.41 mm) | 0.023 in (0.58 mm) |

| Max Diameter | 0.012 in (0.30 mm) | 0.016 in (0.41 mm) | 0.017 in (0.43 mm) | 0.025 in (0.63 mm) | |

| Max Length | 0.0242 in (0.610 mm) | 0.032 in (0.81 mm) | 0.034 in (0.86 mm) | 0.056 in (1.46 mm) | |

| Lead Wires | Nominal Diameter | 0.0007 in (0.02 mm) | 0.0011 in (0.03 mm) | 0.0011 in (0.03 mm) | 0.002 in (0.05 mm) |

| Max Lead Length | 0.312 in (7.9 mm) | ||||

| Lead Material | Platinum Alloy | ||||

| Available Cuts | "K" adjacent or "P" opposite | ||||

| Thermal Time Constant | Still Air @ 25°C (77°F) | 0.8 seconds | 1 second | 1.2 seconds | 1.7 second |

| Plunge into Water | 12 msec | 14 msec | 16 msec | 40 msec | |

| Dissipation Constant | Still Air @ 25°C (77°F) | 0.065 mW/°C | 0.10 mW/°C | 0.12 mW/°C | 0.18 mW/°C |

| Still Water @ 25°C (77°F) | 0.33 mW/°C | 0.50 mW/°C | 0.60 mW/°C | 0.90 mW/°C | |

| Power Rating (In Air) | Max Power Rating | 0.007 W | 0.015 W | 0.015 W | 0.020 W |

| 100% Max to: | 125°C (257°F) | ||||

| Derated to 0% at: | 300°C (572°F) | ||||

| Options |

|

||||

| Thermistor Series: | BR32 | BR42 | BR55 | |

| Body Dimensions | Nominal Diamater | 0.032 in (0.81 mm) | 0.042 in (1.16 mm) | 0.055 in (1.41 mm) |

| Max Diameter | 0.033 in (0.84 mm) | 0.046 in (1.2 mm) | 0.060 in (1.5 mm) | |

| Max Length | 0.084 in (2.1 mm) | 0.095 in (2.4 mm) | 0.120 in (3 mm) | |

| Lead Wires | Nominal Diameter | 0.003 in (0.08 mm) | 0.004 in (0.10 mm) | 0.004 in (0.10 mm) |

| Max Lead Length | 0.312 in (7.9 mm) | |||

| Lead Material | Platinum Alloy | |||

| Available Cuts | "K" adjacent or "P" opposite | |||

| Thermal Time Constant | Still Air @ 25°C (77°F) | 4.5 seconds | 5 seconds | 7 seconds |

| Plunge into Water | 90 msec | 140 msec | 200 msec | |

| Dissipation Constant | Still Air @ 25°C (77°F) | 0.285 mW/°C | 0.33 mW/°C | 0.5 mW/°C |

| Still Water @ 25°C (77°F) | 1.4 mW/°C | 1.65 mW/°C | 2.50 mW/°C | |

| Power Rating (In Air) | Max Power Rating | 0.035 W | 0.042 W | 0.050 W |

| 100% Max to: | 150°C (302°F) | |||

| Derated to 0% at: | 300°C (572°F) | |||

| Options |

|

|||

English

Thermometrics Application Spotlight | NTC Sensor Linearization

Sensors for Healthcare | Amphenol Advanced Sensors - Brochure

Thermometrics Application Spotlight | Thermistors FAQ - Application Spotlight

English

Thermometrics | Temperature Resistance Curves - Reference Guide

Temperature Sensor Solutions | Thermometrics - Brochure

Amphenol Advanced Sensors | Connecting Your World Through Sensing Innovations - OEM Product Catalog

Part numbers are described in the datasheet.