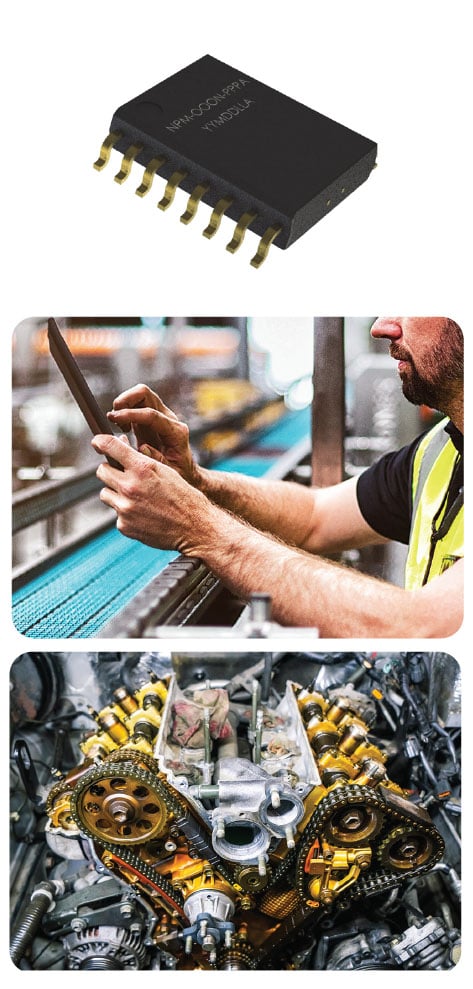

NPM Pressure Molded Pressure Sensor

NovaSensor NPM Pressure-Molded Pressure Sensor is a silicon-based MEMS device using “Backside Absolute Pressure” Technology designed for harsh media exposure with new edge over-molding pressure sensor technology. This new technology eliminates direct contact of the sensing circuitry with the applied media and provides a small footprint. The device is coupled with an ASIC to provide analog ratiometric and SENT output proportional to the applied pressure. NPM is ASIL B compliant.

NPM is molded with PT1907 as a core backside absolute pressure technology developed by NovaSensor. The PT1907 die allows for simultaneous pressure and temperature measurements in chemically aggressive media, including strong bases, most acids and all automotive fluids. The PT1907 product family is based on the P1905 pressure sensor die used in various automotive applications. Similar to the P1905 die, the PT1907 die has outstanding overload capability and excellent long-term stability made possible by the NovaSensor SenStable® process. The integrated on-chip temperature sensor allows for high accuracy measurement of temperature. This data can be used to improve the accuracy of the pressure sensor in the operating temperature range.

Applications:

- Transmission fluid pressure sensing

- Oil pressure sensing

- Fuel pressure sensing

- Harsh media pressure sensing

- Process control systems

Features:

- SOIC footprint

- Operating Temperature Range: -40°C to 150°C

- Pressure Range: 20BarA Target. Custom pressure ranges available upon request.

- Custom range/transfer function upon request

- Accuracy: ±2%

- Harsh media compatibility

- Small package

- ASIL B compliant

- Available in Analog ratiometric and SENT output